The electric vehicle (EV) revolution is here. It is rapidly moving from niche enthusiasm to mainstream adoption. At the core of this transformation is the battery—the energy storage system that powers the motor. To fully understand the industry, the science behind how this technology works, often described as EV battery chemistry explained, is essential because chemistry determines performance.

The battery’s fundamental chemical composition directly influences four crucial areas: the vehicle’s range, its cost (the single most expensive component), its safety profile, and its environmental footprint. Engineers and chemists are constantly battling to optimize these competing factors.

The objective of this article is simple: to break down the science behind lithium-ion EV batteries in plain language. It provides a solid foundation for understanding the choices automakers make and where the technology is headed next.

Table of Contents

Fundamentals of Lithium-ion Batteries

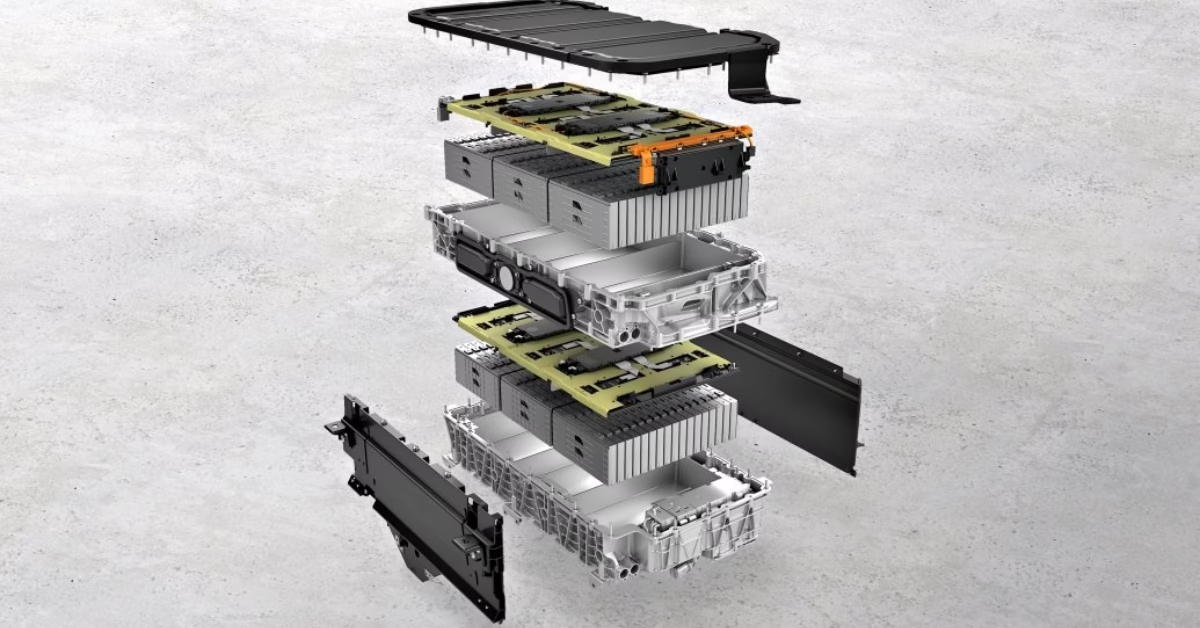

Before diving into specific chemistries like NMC or LFP, it is essential to understand the basic ‘engine’ of every EV battery: the cell. This section breaks down the fundamental physical components and the elegant chemical process that enables energy storage and release.

Composition and Structure

All lithium-ion batteries share a basic architecture, consisting of four core components assembled into individual cells:

- Cathode (Positive Electrode): Determines the cell’s capacity and voltage. In modern EVs, this is typically a lithium-metal oxide compound like NMC or LFP.

- Anode (Negative Electrode): Stores the lithium ions when the battery is fully charged. Graphite is the most common material used here due to its layered structure.

- Electrolyte: A liquid or gel medium that acts as a highway, allowing lithium ions to travel between the anode and the cathode.

- Separator: A thin, porous film physically preventing the anode and cathode from touching, which would cause a short circuit.

How They Work

The process of charging and discharging a lithium-ion battery is globally known as intercalation.

Charging (Storing Energy)

- Input: Electrical energy is forced into the cell.

- Ion Movement: Positively charged lithium ions travel from the cathode (positive) through the electrolyte.

- Storage Action: The ions “intercalate” (nestle) into the layered structure of the graphite anode (negative).

- Result: This process is fundamentally how EV batteries store and release energy.

Discharging (Releasing Energy/Driving)

- Ion Movement: Lithium ions travel back from the anode to the cathode.

- Energy Release: This movement releases the stored electrical energy.

- Powering the Vehicle: The energy powers the motor, as electrons flow through the external circuit (the car’s systems) to complete the loop.

EV Batteries vs. Consumer Batteries

While the core chemistry is similar to that in laptops or phones, EV batteries are fundamentally different due to:

- Scale and Power: They handle massive power demands and high voltage requirements.

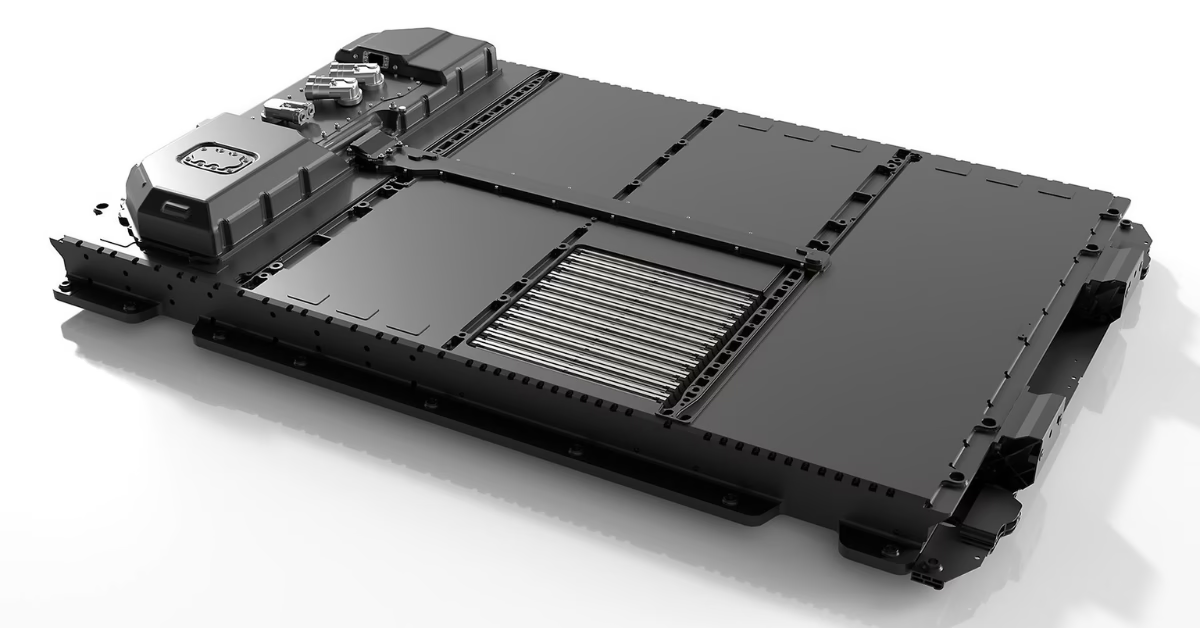

- Thermal Management: They require robust cooling systems.

- Control System: They utilize sophisticated Battery Management Systems (BMS) for safety and optimal performance.

Key Types of Lithium-ion Chemistries in EVs

Automakers choose battery chemistry based on their target market—balancing high performance with cost and safety.

Lithium Nickel Manganese Cobalt (NMC)

NMC batteries are known for their high energy density and good performance across a wide range of temperatures. They are widely used by European and Korean manufacturers (e.g., BMW, Hyundai). The primary trade-off is their reliance on cobalt, which contributes to higher material costs and presents ethical sourcing challenges.

Lithium Nickel Cobalt Aluminum Oxide (NCA)

Similar to NMC, NCA offers extremely high density and efficiency. It is most famously used by Tesla, although the company is rapidly diversifying. Because of its high energy density, NCA requires sophisticated active cooling and management systems to ensure safe operation.

Lithium Iron Phosphate (LFP)

LFP batteries have emerged as a dominant force in base-model and budget EVs. Their key advantages are low cost (due to the absence of nickel and cobalt), long cycle life (they can be charged and discharged many more times), and superior thermal stability, making them inherently safer. Their main disadvantage is lower energy density, which translates to less range for a given battery weight.

Other Emerging Chemistries

Future innovations like LMFP (Lithium Manganese Iron Phosphate) are attempting to bridge the gap between LFP’s safety and NMC’s density. Solid-state batteries are the most anticipated next step, aiming to replace the liquid electrolyte with a solid one to achieve massive leaps in both energy density and safety. This ongoing development is central to the discussion around NMC vs LFP battery chemistry and what comes next.

| Chemistry | Energy Density | Cost | Cycle Life | Safety | Use Cases |

| NMC | High | High | Good | Good (Requires Cooling) | Mid-to-High-Range Performance EVs |

| NCA | Very High | High | Good | Good (Requires Advanced BMS) | High-Performance EVs (e.g., Tesla) |

| LFP | Medium | Low | Excellent | Excellent (Thermally Stable) | Base-Model, City, and Commercial EVs |

Advantages of Lithium-ion Batteries in EVs

Lithium-ion batteries became the industry standard due to several key performance characteristics that make them ideally suited for vehicle use.

High Energy Density

The primary advantage of lithium-ion batteries is their high energy density—they can store a large amount of energy in a small, lightweight package. This is the crucial link between chemistry and range. Modern lithium-ion cells can store far more energy per kilogram than older technologies like Nickel-Metal Hydride (NiMH) or lead-acid, making long-distance travel viable for the first time in an electric vehicle.

Efficiency and Longevity

Most EV batteries are designed to last for 500 to 3,000 charge/discharge cycles. The longevity is highly influenced by external factors, especially temperature. The Battery Management System (BMS) plays a critical role here, using software algorithms and hardware to ensure every cell operates within its optimal voltage and temperature range, thereby maximizing the battery’s lifespan and maintaining efficiency.

Fast Charging Capabilities

The ability to fast charge is not just about the charging station; it’s about the battery chemistry itself. Improved chemistries, combined with highly accurate BMS monitoring, allow for higher power input (faster charging). However, the charging curve differs: NMC batteries often charge quickly to 80% capacity before slowing down significantly, while LFP batteries can typically maintain a more consistent, if slightly slower, charge rate closer to 100%.

Safety, Health, and Battery Management

Understanding the EV battery cell composition and materials is vital to discussing safety.

Thermal Management and Runaway Prevention

The greatest safety concern is thermal runaway, where heat generated in one cell spreads rapidly to neighboring cells. EV cooling systems—which can use liquid coolants, air, or phase-change materials—are designed to efficiently dissipate heat and prevent this runaway effect. The physical structure and spacing of cells are also engineered to mitigate heat propagation.

Common Safety Risks

Safety risks typically arise from severe conditions, such as internal short circuits caused by manufacturing defects, extreme overcharging, or physical damage (like punctures in an accident). The inherent thermal stability of LFP chemistry often makes it the safest option, whereas high-density chemistries like NCA require more intensive management.

Battery Management System (BMS)

The BMS is the brain of the battery pack. It constantly monitors:

- Voltage of every individual cell.

- Temperature across multiple points.

- Current entering and leaving the pack. By maintaining optimal conditions, the BMS ensures maximum safety and performance while preventing conditions that could lead to damage or thermal events.

Understanding Degradation

Capacity fade occurs naturally over time. The primary causes of degradation include the build-up of the Solid Electrolyte Interphase (SEI) layer on the anode and lithium plating, where lithium metal deposits on the anode surface, reducing the battery’s capacity and efficiency.

Tips to extend EV battery life often center around minimizing exposure to extreme states of charge (like holding it at 100% or 0% for long periods) and avoiding exposure to extreme temperatures.

Environmental and Cost Considerations

Beyond performance and safety, EV battery chemistry profoundly impacts the global supply chain, material costs, and long-term environmental sustainability of electric vehicles.

Resource Extraction and Sustainability

The mining of raw materials like lithium, cobalt, and nickel required for battery manufacturing carries significant environmental and social impacts. Companies face growing pressure regarding ethical sourcing challenges and corporate accountability related to water use, land disruption, and labor practices. Transitioning to cobalt-free and nickel-free chemistries like LFP is one way the industry is addressing sustainability concerns.

Recycling and Second-Life Use

Once an EV battery is no longer suitable for vehicle use (typically retaining 70-80% of its original capacity), it doesn’t immediately become waste. Second-life use involves repurposing these batteries for less demanding applications, such as home energy storage or grid stabilization. Government initiatives and advancements in recycling technology (like hydrometallurgy) are crucial to efficiently recovering valuable materials and creating a truly circular economy.

Cost Factors

Chemistry is the biggest factor in battery pricing and, consequently, vehicle affordability. LFP batteries are currently the most cost-effective option. Trends are pushing towards even cheaper solutions, such as sodium-ion batteries, which promise materials costs that are significantly lower than lithium-ion chemistries.

The Future of EV Battery Chemistry

The lithium-ion battery is not a static technology; it is rapidly evolving. Driven by the need for greater range, faster charging, and lower material costs, chemists and engineers are aggressively pursuing next-generation technologies that promise to revolutionize the EV landscape within the next decade.

Ongoing Research and Innovations

The quest for the perfect battery is relentless. The most significant areas of ongoing research include:

- Solid-State Batteries: Expected to provide higher energy density, faster charge rates, and greatly enhanced safety by eliminating the flammable liquid electrolyte.

- Sodium-ion (Na-ion): Offers extremely low material cost and excellent cold-weather performance.

- Silicon Anodes: Replacing traditional graphite with silicon can significantly boost energy density, though stability issues remain a hurdle.

Market and Industry Trends

Automakers are increasingly diversifying their battery supply chains. Tesla, BYD, and Ford are notable players aggressively adopting LFP for their standard-range vehicles, reserving NMC and NCA for long-range and performance models. Forecast to 2030, a multi-chemistry approach is expected to dominate, with solid-state technology potentially entering the premium market segment.

FAQs

What is EV battery chemistry?

EV battery chemistry refers to the specific combination of materials used in the cathode (positive electrode), such as lithium nickel manganese cobalt (NMC) or lithium iron phosphate (LFP), which determines the battery’s energy density, cost, safety, and lifespan.

Why do EVs use different battery chemistries?

Different chemistries are used to balance competing goals: high-performance EVs use high-density chemistries like NMC or NCA for maximum range, while commercial or budget EVs prioritize low cost and long cycle life using LFP.

What makes LFP batteries safer than NMC?

LFP (Lithium Iron Phosphate) is inherently safer because its chemical structure is more stable at high temperatures. The iron phosphate material releases oxygen much slower when heated, making it far less prone to the rapid, chain-reaction heat generation known as thermal runaway.

How does temperature affect EV battery performance?

Extreme temperatures reduce performance. Cold weather temporarily lowers the battery’s ability to discharge (reduced range) and accept charge. Hot weather is more damaging long-term as it accelerates the degradation processes (capacity fade).

Are solid-state batteries really the next big step?

Yes, solid-state batteries are widely considered the next major breakthrough. They promise to replace the flammable liquid electrolyte with a solid ceramic or polymer, offering significantly higher energy density (more range), faster charging, and improved safety.

Chemistry as the Core of the EV Revolution

The performance of an electric vehicle is defined by its core chemistry, not just the pack’s size. This focus on the inner workings is what we mean by EV battery chemistry explained. Chemistry determines range, safety rating, cost, and overall sustainability.

Automakers choose chemistries—like high-density NMC/NCA or cost-effective LFP—based on complex trade-offs. These decisions balance engineering, materials science, and market demands.

Understanding the fundamentals of lithium-ion battery chemistry empowers consumers. This knowledge helps them make smarter EV choices. It ensures their vehicle aligns with their needs and values as the revolution accelerates.